What is Shrink Wrap vs Stretch Wrap and How is it Used in Packaging Operations?

While the terms shrink wrap and stretch wrap are often used interchangeably, they aren’t actually the same thing. While they may sound similar to someone unfamiliar with packaging, their materials, how they are applied and the purposes they serve are quite different. Understanding the difference between shrink wrap and stretch wrap is critical for any business that ships or stores products. This guide will set the record straight on the differences between the two, specifically how and when you should use them.

What is Shrink Wrap? Looking Below the Surface Layer

At its most basic, shrink wrap – also known as heat-seal shrink film – is a versatile plastic film that, when heat is applied, shrinks tightly to conform to the shape of the object it’s covering.

Unlike stretch wrap, which relies on tension and elasticity, shrink wrap changes its form to create a tight, protective and tamper-resistant seal.

Common Shrink Film Materials

Shrink films are commonly manufactured from a few different types of plastic, with two materials – polyolefin and polyethylene – being the most common today:

- Polyolefin (POF): Polyolefin shrink film is the most popular, premium choice for retail packaging. It is durable, suitable for food contact, and offers great clarity for an attractive appearance.

- Polyethylene (PE): This material is often used for heavier applications, such as bundling cans or bottles into multipacks. It offers durability and good protection, though typically with lower clarity than POF.

- PVC: Once very common, heat-sensitive PVC film is used less frequently today. While it shrinks easily at low temperatures, it can become brittle in storage and releases harmful fumes when heated, requiring excellent ventilation.

How Does Shrink Wrapping Work?

Shrink wrapping is valued for its versatility and ability to protect bulky or irregular shapes that standard product packaging simply cannot accommodate. While standard palletised boxes are usually best secured with stretch wrap, shrink wrapping is the go-to solution for unique items that need a secure load and robust weather-proofing.

The process uses a heat gun to apply heat to a low density polyethylene plastic film. As the film shrinks tightly around the object, it conforms perfectly to every contour, forming a durable, sealed barrier that keeps out dust, dirt, moisture, and air.

At Azapak, our Heat Shrink Wrap solutions are tailored for larger industrial applications rather than small retail packs like DVDs. Our products are ideal for creating a heavy-duty protective barrier for many types of machinery, equipment, and vehicles. We support applications ranging from full boat wraps for watercraft dealers and fabricators, right up to securing items as large as helicopters for transport or storage.

|

Step 1: Cover the ItemFirst, the object must be covered with the shrink film. Azapak offers large-format film options suitable for your item's size, such as:

The pallet or other items are left loosely sealed at this stage, with any excess gathered at the base or sides. |

|

Step 2: Apply Heat with a Heat GunFor industrial shrink wrapping, you heat-shrink the plastic using a powerful, handheld Heat Shrink Gun. You work your way around the object, applying the heat to the plastic to achieve an even shrinkage effect. The film's molecules react by reorganising, causing the film to shrink dramatically and conform tightly to the shape of your load. This process "locks" the load together and fuses the film into a single, durable, and protective layer. This method is cost-effective and highly versatile, allowing you to secure items of any shape or size, from a single package to a large, irregular machine for outdoor storage. |

Shrink Wrap Benefits

Using industrial heat shrink wrap offers a level of protection and security that other packaging methods can't match. When properly applied, it creates a secure, weather and puncture-resistant shell with a neat appearance well suited to public-facing retail settings.

Protection from the Elements

Once heated, shrink wrap creates a seamless protective barrier that completely encases the load to protect it from moisture, dust, and weather exposure.

Ideal for Irregular Shapes

This is a key benefit of shrink film. The shrinkable plastic’s conformability to any shape once heated makes it easy to wrap items with odd edges or irregular forms. Think of large machines, industrial parts or equipment that are difficult to pack in a standard box.

Secure, Tamper-Evident Sealing

The heat-sealing process creates a secure, drum-tight package. It is immediately noticeable if this seal has been cut, punctured or otherwise compromised. This tamper-evident benefit is crucial for protecting high-value loads or sensitive products from pilferage and contamination during transport or storage.

Main Differences Between Shrink Wrap vs Stretch Wrap

Now that you know what shrink wrap is, let's explore the different methods, applications and attributes associated with each category of film.

| Feature | Shrink Wrap | Stretch Wrap |

|---|---|---|

| Primary Use | Bundling products, retail presentation, tamper resistance. | Pallet wrapping, load containment, securing items for transport. |

| Application | The film is usually hand wrapped loosely around the packaging, then heat is applied using heat guns or specialised heat tunnel shrink wrap systems to shrink the film. | Tension is applied (elastic nature) to stretch the film tightly around the pallet. |

| Material | Polyolefin (POF), Polyethylene (PE) | Linear Low-Density Polyethylene (LLDPE) |

| Appearance | Shrinks tightly to conform to the product, often high-clarity and glossy. | Will wrap tightly around a load, remains flexible. |

| Equipment | Requires heat source, for example a heat gun or shrink tunnel. | Can be applied manually or with a stretch wrap machine (pallet wrapper). |

When Should I Use Stretch Wrap vs Shrink Wrap?

The right choice depends entirely on your goal, as each product is a high-performance solution for a different task: load containment vs product sealing.

When Stretch Wrap is Better

You should use stretch wrap when your primary goal is to prevent large or heavy loads of boxes from shifting during transport, specifically when you wrap pallets. Its main job is binding loads together to prevent shifting, damage, or toppling during storage and transport. It’s not Glad Wrap; it is a heavy-duty industrial film engineered for high tension and puncture resistance.

If you need to secure a stack of boxes, stretch wrap from our Pallet Wrapping range is the correct packaging solution. You can learn more about the different types of stretchable plastic film – including the differences between cast stretch film and blown stretch film – available in our Ultimate Guide to Stretch Wrap Usage.

You can apply stretch wrap by hand wrapping (we detail the manual application process in our guide on How to Wrap a Pallet by Hand) or by using machine stretch film with an automatic pallet wrapping machine.

When Shrink Wrap is Better

You should use shrink wrap when your goal is total product protection and presentation. It is the premium solution for retail packaging and public-facing environments where appearance matters, as this wrap forms a neat, highly transparent finish with added tamper resistance.

Industrially, shrink wrap is also a powerful tool for heavy-duty protection. Because it shrinks to form a complete, fused seal, it offers an exceptional level of water and dust protection for items like machinery or equipment being stored outside. This ability to create a high IP-rated (Ingress Protection) barrier is a key strength unique to the shrink wrapping process.

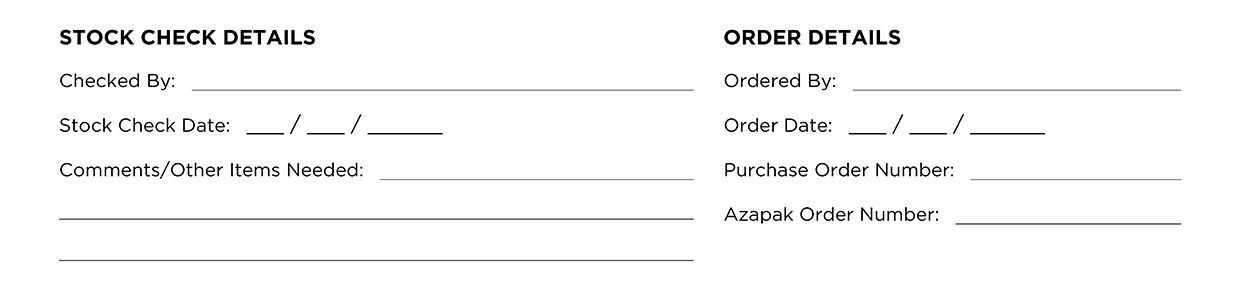

Pallet Wrap Analysis Service

Not sure where to start or looking to optimise your pallet wrapping and load containment? Azapak offers a FREE Pallet Wrap Analysis that gives you detailed information about your current material usage and compares it against industry best practice. Over 73% of companies we review are wasting money and creating unnecessary waste because of inappropriate film choice, poor machine settings or ineffective wrap force.

Our specialists assess how your pallets are wrapped, identify whether you’re using too much or too little film, and recommend practical improvements such as more efficient pre-stretched film options. This service can help you:

- Reduce film consumption and cut costs

- Optimise load stability and minimise product damage

- Ensure workplace safety and WHS compliance

With more than 20 years of experience and hundreds of successful assessments, Azapak helps you choose product and equipment investments that will yield a good return for your business. Book your free pallet wrap analysis today! Need more info? Simply call us on 1300 255 725 or email sales@azapak.com.au.

Shrink Wrap vs Stretch Wrap FAQs

Find the Right Packaging Supplies at Azapak

If you want to explore the role of heat sealing in your packaging process or optimise your pallet wrapping, Azapak is your complete packaging supplier. We stock a complete range of packaging products to suit any application.

Need help deciding on the right film, advice on different types, thicknesses and application methods? Our packaging experts are here to help. Call us on 1300 255 725 or email sales@azapak.com.au to discuss your business’s packaging needs.