The Ultimate Guide to Stretch Wrap Usage

Stretch wrap is a packaging essential for modern warehouses and distribution centres. While its main job is to secure pallet loads and protect products during handling and transport, there’s a wide range of film types on the market. Each is designed for different stretch wrap uses and industry-specific applications.

From film strength and thickness to colour and application method, each variation plays a role in performance. This blog post breaks down the different types of stretch wrap so you can choose the best option for your products, workflow and packaging needs, whether you are wrapping by hand or using a pallet wrapper.

What is Stretch Wrap and How is it Made?

|

Stretch wrap, also known as stretch film, is a highly stretchable plastic film that is wrapped around items to keep them secure. Typically made from linear low-density polyethylene, it is strong and flexible. Its main purpose is to bundle boxes together on a pallet for safe transportation, but it has various applications. The film clings to itself, creating a tight, protective layer that guards products against dust, dirt, and moisture. Because it is a simple and reliable method for load containment, it remains a highly cost-effective solution for businesses of all sizes. |

|

Before You Wrap: Key Stretch Film Uses For Consideration

Before you wrap, it’s important to understand what sets different stretch wrap films apart. The nature of your goods, your storage environment and your shipping process will all influence the best choice.

Blown vs Cast Stretch Film: Puncture Resistance vs Clarity

The manufacturing process creates two main categories of stretch film, each with distinct advantages.

Cast Stretch Wrap: This is manufactured by extruding melted resin through a flat die onto a chilled roller, which cools the film rapidly. The process creates a film known for its exceptional clarity and quiet operation. Cast Stretch Wrap: This is manufactured by extruding melted resin through a flat die onto a chilled roller, which cools the film rapidly. The process creates a film known for its exceptional clarity and quiet operation.

Attributes:

|

Blown Stretch Film: Produced by extruding melted resin through a circular die to form a bubble. The bubble is then flattened and cooled, resulting in a tougher film with superior cling and durability. Blown Stretch Film: Produced by extruding melted resin through a circular die to form a bubble. The bubble is then flattened and cooled, resulting in a tougher film with superior cling and durability.

Attributes:

|

Colour and Opacity: Visibility vs Security

While clear film is the standard for its visibility, coloured and opaque options serve specific purposes.

- Clear Pallet Wrap – Also known as natural film, it’s the go-to choice when stock visibility and barcode scanning are required.

- Black Pallet Wrap – Black wrap conceals the identity of valuable or sensitive goods, deterring theft and protecting items from the sun’s UV rays.

- White Stretch Film – Offers the same privacy and security as black film. Our ROAR WRAP Blown White Stretch Wrap is an excellent opaque choice.

- Assorted Colours – Coloured films are ideal for quick product identification, organising stock rotations, and reinforcing company branding. Our Grip Film - Coloured Stretch Wraps come in tints like blue, red, and green.

Film Gauge and Dimensions: Matching Strength to the Task

- Film Gauge – Gauge refers to different thicknesses. A thicker film (e.g. 25µm) offers greater puncture resistance for heavier loads (or those with sharp edges), while a thinner film (e.g. 15µm) is suitable for lighter, uniform products.

- Roll Width and Length – Hand rolls are typically 450mm or 500mm wide, while machine rolls are generally 500mm. We also offer a 600mm-wide Securewrap product. The length varies, but choosing the right dimensions optimises material usage and operator efficiency.

Stretch Film Uses by Application Method

The most significant factor in choosing stretch films is how you plan to apply it. Azapak offers specialised solutions for every method, from manual stretch wrapping to fully automated systems.

Hand Stretch Wrap: For Manual Application & Flexibility

| Hand Pallet Stretch Wrap is designed to be applied manually. It’s the perfect solution for businesses with lower throughput, for use in areas without access to power, or as a backup for a pallet wrapping machine. Hand film offers great flexibility to wrap pallets of various shapes and sizes. For improved ergonomics and consistent tension, we recommend using a tool like our Heavy-Duty Pallet Wrap Dispenser. |  |

Machine Stretch Film: For High-Volume, Automated Wrapping

| For businesses that wrap a significant number of pallets daily, a stretch wrap machine is a game-changer. Machine Pallet Wrap is engineered specifically for use with these pallet wrapping machines. It is designed to be stretched at high ratios, offering superior consistency, speed and load containment compared to hand application. |  |

Bundling Wrap: The Practical Hand Stretch Film for Smaller Items

| Not all wrapping involves a full pallet. Bundling Wrap is a narrow-width film, typically 100mm wide, that comes on a convenient dispenser. It’s an excellent replacement for tape, twine or strapping. Common uses include securing small boxes together, wrapping table legs, bundling lengths of timber or pipe and protecting furniture components when preparing them for opening or delivery. It is commonly used by removalists, manufacturing plants, e-commerce fulfilment centres and despatch areas in warehouses. |  |

Orbital Stretch Wrap: For Long and Awkward Loads

|

How do you wrap items that can't simply be placed on a pallet, like a door, a window or a long pack of timber? The answer is Orbital Stretch Wrap. Designed for orbital, spiral and horizontal wrapping machines, this film feeds items through a rotating ring for a tight, all-sided seal. Made from high-quality cast stretch film, it stretches up to 230%, clings only to itself, stays clear for easy ID and barcode scanning. It’s also fully recyclable. |

|

Ventilated Stretch Film: Perforated Plastic Wrap for the Food Industry

|

Standard stretch film can trap heat and moisture, risking product damage from spoilage or rust. Ventilated stretch wrap is the intelligent solution. Engineered with die-cut holes, this film allows air to circulate freely throughout the pallet. This constant airflow is crucial, as it lets heat and moisture escape, which prevents the damaging condensation (or ‘pallet sweat’) that occurs when moving goods between different temperature zones. This makes it essential for the food industry and beyond. It allows fresh produce to breathe, hot-fill products like baked goods and beverages to cool rapidly, and frozen goods to freeze faster. Azapak provides options for any scale:

|

|

The Power of Pre-Stretch: An Efficient and Environmentally Friendly Solution

One of the biggest advantages of using a modern stretch wrap machine is its pre-stretch capability. Pre-stretching is the process of elongating the film inside the machine's "power head" before it's rolled around the pallet.

High-performance machines like the Vanto VW-230 Semi-Auto Pallet Wrapper can pre-stretch film by up to 300%. Our Securewrap Machine Stretch Wrap and extra-efficient Diamondwrap Machine Stretch Wrap are ideal for use with power pre-stretch machines.

This means one metre of film off the roll becomes up to four metres of pre-stretched film applied to your load, reducing overall stretch wrap usage. This maximises your film efficiency and delivers several key benefits:

- Cost Savings – You use significantly less plastic wrap per pallet, drastically reducing your material costs.

- Enhanced Load Security – Stretched film has excellent elastic recovery. It constantly tries to shrink back to its original size, resulting in a tighter, more secure load that is less likely to shift during transport.

- Environmental Benefits – Reducing your plastic consumption is not just good for your bottom line; it's better for the environment.

Stretch Wrap vs Shrink Wrap: What's the Difference?

Though the terms are often used interchangeably, stretch wrap and shrink film are two different products with different uses.

- Stretch Film – A highly stretchable plastic film wrapped around items. Its inherent elasticity keeps the load tight. No heat is required.

- Shrink Wrap/Shrink Film – Placed loosely over an item or items, and heat is then applied (with a heat gun or through a heat tunnel) to make the film shrink and conform tightly to the product's shape. It is more commonly used for retail products for example, not for transit packaging.

Find the Right Stretch Wrap for Your Needs at Azapak

From securing fragile items and light loads to stabilising heavy-duty building materials, there are stretch wraps for every application across various industries.

Azapak is your partner in quality packaging. We help our customers across all industries optimise their packaging processes. Need help selecting the right hand wrap or want to explore the bottom-line benefits of a pallet wrapping machine? Our team is here to help.

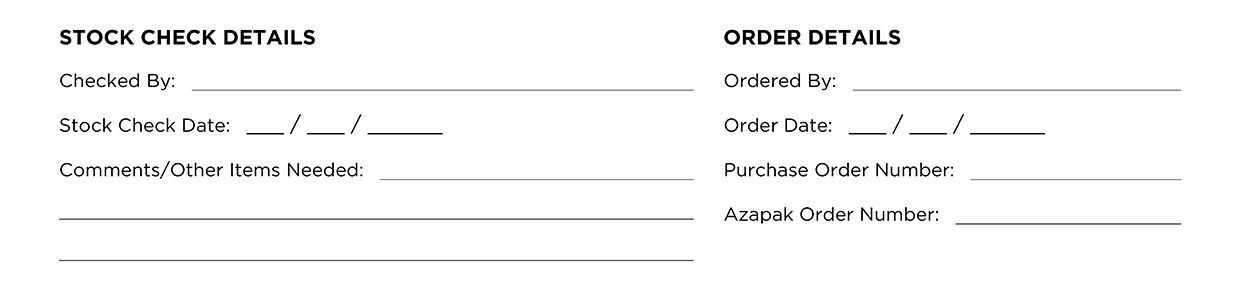

Pallet Wrap Analysis

Not sure where to start or looking to optimise wrapping and reduce costs? Azapak offers a FREE Pallet Wrap Analysis that gives you detailed information about your current use and compares it against industry best practice. Over 73% of companies we review are wasting money and creating unnecessary waste because of the inappropriate film choice, poor machine settings or ineffective wrap force.

|

Our specialists assess how your pallets are wrapped, identify whether you’re using too much or too little film, and recommend practical improvements. This service can help you:

With more than 20 years of experience and hundreds of successful assessments, Azapak helps you find solutions you can easily apply in your business. Book your free pallet wrap analysis today!

Book FREE Pallet Wrap Analysis Need more info? Simply call us on 1300 255 725 or email sales@azapak.com.au. |

|