What is a Heat Sealer: Types & Uses Explained

A heat sealer is a piece of equipment that uses a precise impulse of heat and pressure to join layers of thermoplastic material, creating a secure, air and water-tight weld. While the technology is commonplace across food industries for maintaining hygiene and shelf life, it can be equally useful in the modern warehouse. In a busy despatch centre, loose items are a liability, and a heat-sealing machine provides the speed and consistency needed to secure everything from spare parts to textile bundles.

Unlike tape or staples, which can peel or snag, a heat sealer fuses the packaging material itself, creating a bond that is often stronger than the bag. This ensures that small components like screws, washers, or electrical fittings don’t get lost during transit or long-term storage. It is distinct from shrink wrapping; rather than shrinking film around a product, a sealer creates a defined, airtight closure at the opening to prevent oxidation, contamination and provide added tamper evidence.

At Azapak, we specialise in heavy-duty benchtop and foot-operated sealers designed for the rigours of Australian warehouses rather than kitchen benches. Whether you are kitting hardware for flat-pack furniture or protecting industrial components from dust, reliable equipment is key. In this guide, we’ll break down the specific operational benefits of heat sealing for industrial packaging needs and help you find the right heat sealer for your business.

How Do Heat Sealers Work?

What is a heat sealer, and how does it work? The concept behind a heat sealer is relatively simple but highly effective. The sealing machine uses a heating element – often a nichrome wire covered by teflon tape to prevent sticking – to apply heat to the packaging materials.

When the sealing arm is lowered, the element heats up, melting the thermoplastic layers. Once the heat stops and the material cools (usually within seconds), the two layers fuse together to form a permanent, tamper-evident seal. This ensures product integrity, prevents contamination, and improves the seal strength of the sealed package.

Most modern units, like the ones available at Azapak, allow you to adjust the sealing time to ensure consistent seals regardless of whether you are using thin plastic films (like cellophane bags) or thicker materials.

Different Types of Heat-Sealing Machines

While there are many specialised machines like band sealers (which use a conveyor belt for high-speed applications) or constant heat sealers (where the bars stay hot continuously), the most common types found in general warehousing and dispatch are impulse heat sealers.

|

1. Impulse Heat SealersImpulse sealers are the industry standard for most general packaging tasks, commonly used by small businesses and large operations alike. Unlike constant heat sealers, an impulse sealer utilises impulse heat technology, meaning it only uses electricity to heat the element when the sealing jaw is closed. This makes them:

Azapak’s 1000 Series and 1100 Series models are classic examples of desktop impulse sealers. They are perfect for sealing spare parts, documents, or small retail items. |

|

2. Heat Sealers with CuttersFor businesses that create their own bags from continuous rolls of poly tubing, a heat sealer with a built-in cutter makes a big difference. Our 1100 Series Heat Sealers feature a sliding blade that trims the excess plastic immediately after the seal is made. This creates a neat, professional finish without the need for scissors. This is a game-changer for high-volume dispatch areas where speed and presentation matter. Maintenance Tip: For high-volume operations using a heat sealer with a cutter, you might need to replace the blade regularly. Keeping spare cutting blades on hand ensures minimal downtime for your heat-sealer machine for plastic packaging. Azapak stocks spare parts to keep your heat sealers running smoothly. We offer repair kits that make replacing parts quick and easy. Azapak also offers service and routine maintenance for your heat sealer, handled by our in-house machinery team. |

|

3. Foot Operated Heat SealersWhen your staff are handling heavy bags or need both hands to position the product correctly, a desktop sealer can be cumbersome. This is where Foot Operated Heat Sealers shine. These pedestal-style units use a foot pedal to activate the sealing mechanism. This leaves both hands free to hold the packaging materials flat and straight, ensuring consistently reliable seals, and it reduces the user’s physical fatigue. They are often used for pet food products, bulk powders, or larger industrial components. |

Practical Applications: Who Needs a Heat Sealer?

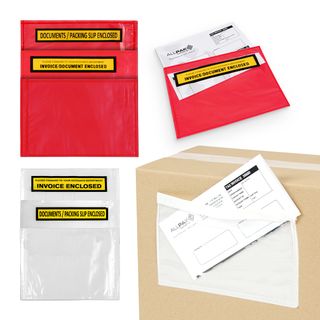

While often associated with food packaging and medical supplies, where vacuum sealers are frequently utilised to increase shelf life, heat-sealed packaging systems are the workhorse of the industrial packaging world. From automotive warehouses to e-commerce fulfilment centres, here is how Azapak clients utilise this equipment to reduce product damage and loss.

Hardware Kitting and Assembly

For manufacturers of flat-pack furniture, machinery, or automotive accessories, "kitting" is a critical stage. This involves grouping necessary assembly components—screws, bolts, allen keys, and washers—into a single package. Using a heat sealer with continuous poly tubing allows operators to create custom-length bags for these heavy, irregular items. A secure heat seal ensures these small, sharp objects don’t burst through the packaging or get lost in the master carton, preventing the dreaded customer complaint of "missing parts."

Warehousing and Spare Parts Storage

Dust, moisture, and oxidation are the enemies of stored inventory. In automotive and engineering warehouses, metal parts left exposed on shelf bins can degrade over time. Heat-sealing spare parts in heavy-duty poly bags provides a protective barrier against the warehouse environment. It also keeps specific SKUs (Stock Keeping Units) separated and clearly visible. Azapak’s 600mm sealers are particularly popular here for accommodating larger mechanical components.

E-commerce and Textile Protection

For online retailers shipping clothing, bedding, or soft furnishings, water damage during delivery is a major risk. A heat-sealed bag offers a watertight layer of protection that tape simply cannot match. Furthermore, heat sealing provides a professional, "factory-fresh” presentation. It proves to the customer that the item hasn't been opened or tried on since it left your dispatch bench. It also allows you to compress bulky items slightly before sealing to reduce cubic shipping volume.

Bulk Repackaging and Distribution

Many businesses receive stock in bulk, such as 1,000 unit sacks of industrial fasteners or electrical connectors, and need to break them down into smaller retail-ready packs (e.g. packs of 10 or 50). A benchtop heat sealer allows for rapid repackaging. By using pre-printed bags or applying a label after sealing, wholesalers can quickly turn bulk inventory into shelf-ready retail products without needing expensive automated machinery.

General Hygiene and Spill Prevention

While Azapak focuses on industrial goods, many of our clients handle liquids, powders, or granular products (like grout, fertilisers, or cleaning chemicals). Heat sealing is the most effective way to prevent leakage. If a cap loosens during transit, a heat-sealed outer bag contains the spill, preventing it from ruining the rest of the pallet or parcel. This secondary containment is a standard requirement for many couriers handling potentially messy or sensitive products.

How to Choose the Right Heat Sealer

Selecting the correct unit depends on three main factors: material, width, and volume.

1. Material Type and Thickness

What are you trying to seal?

- Polyethylene (PE) and Polypropylene (PP): These are standard thermoplastic material films compatible with impulse heat sealers.

- Poly Cello Films or Laminates: These often require a wider seal or higher heat.

- Thicker Materials: If you are using heavy-gauge plastic (e.g., 200um+), you may need a machine capable of achieving higher levels of heating, such as one with dual heating elements (top and bottom) or thicker bags. However, for standard 100um poly bags, a standard impulse sealer is perfect.

2. Width of the Product

The sealing machine must be wider than the bag you are sealing. If your bag is 300mm wide, a 300mm sealer is too tight; you should opt for a 400mm or 600mm heat sealer to ensure you can seal the entire width without struggle.

3. Production Volume

- Low Volume: A standard hand-operated desktop sealer (1000 Series) is sufficient.

- Medium to High Volume: If you are sealing hundreds of bags a day, a Foot Operated Heat Sealer will significantly reduce operator fatigue and increase speed.

- High Speed: For automated lines, businesses might look at L-bar sealers or band sealers, though these are significantly more expensive than manual options.

Maintaining Your Equipment

To ensure your machine continues to provide consistent seals, basic maintenance is required. Over time, the heating elements and Teflon tape (the fabric strip over the wire) will wear out.

If the Teflon cover wears through, the plastic will stick to the wire, causing the wire to snap. Azapak stocks Heat Sealer Repair Kits, which include replacement wires and Teflon strips. Changing these consumables regularly is the best way to keep your machine running smoothly.

Ready to Seal the Deal?

Make your packaging process airtight with an efficient heat-sealing solution. Our range of heat seal machines includes everything you need to get started, including models to suit all budgets, film rollers for easy dispensing of your plastic tubing or other materials, and heat seal repair kits.

Still have questions on how to use a heat sealer in your packaging operation? Call us on 1300 255 725 or email sales@azapak.com.au to speak to an expert.