What is Water-Activated Tape & Why it’s a Game Changer

As public opinion and environmental regulations shift, many Australian businesses are looking for ways to reduce plastic consumption. This is especially true for public-facing brands and e-commerce retailers who are keen to leverage packaging to reinforce a positive image while also satisfying practical requirements. In short, the ideal combination of aesthetics, eco-friendly credentials and effectiveness is the new standard for packaging solutions.

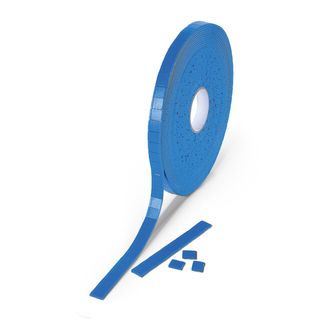

Water-activated tape, also known as gummed tape, has become a popular choice for businesses seeking a strong, tamper-evident, and sustainable way to seal boxes. Made from natural kraft paper and a starch-based adhesive, this paper-based packaging tape delivers a professional finish while removing a whole lot of plastic from your operation’s overall usage.

How Does Water-Activated Tape Work?

Water-activated packaging tape is made from 100% recyclable and renewable resources. It typically consists of two key components:

- Kraft paper: With a pleasant and natural light brown colour, this durable outer layer provides a rigid surface you can print on. Sourced from FSC-certified forestries and fully recyclable.

- Starch-based adhesive: A non-toxic, plant-based glue that becomes sticky when moistened with water. Poses no issues for recyclability or compostability.

When activated, this adhesive fuses with cardboard fibres that make up boxes and cartons. Once dry, a secure seal that’s resistant to tampering, temperature changes, and other stresses is created. Unlike plastic tape, it doesn’t just stick on top, but bonds into the cardboard surface, forming one strong layer that’s tough to remove without leaving visible damage.

Why Businesses Are Making the Switch to Gummed Tape

From small businesses sending e-commerce parcels to industrial manufacturers sealing heavy cartons, more companies are moving to water-activated tape. Australia-wide business owners and their customers are increasingly interested in finding ways to reduce plastic consumption without compromising on performance, and water-activated packing tape is a perfect example of how to do this.

Gummed tape / water-activated tape provides a range of benefits:

1. Eco-Friendly and SustainableIs water-activated tape eco-friendly? Made entirely from renewable resources, water-activated tape is recyclable. Since it’s crafted from paper and starch-based adhesive, there’s no need to remove the tape before recycling cardboard boxes. This makes it the perfect alternative to conventional packaging tape for businesses looking to reduce plastic use, demonstrate care for the planet and cultivate a more ethical brand your customers (and our environment) will love. 2. Tamper-Evident, Secure SealThe activated tape bonds directly with the carton fibres, creating a stronger, more reliable closure than pressure-sensitive options. Once applied, it’s impossible to remove without visibly damaging the surface, creating a clear deterrent to help stop any tampering or theft during transport. 3. Professional PresentationThe natural brown kraft finish of gummed tape gives packages a clean, professional look that complements sustainable brand identities. It’s ideal for businesses that value presentation and want to make their parcels stand out for the right reasons. |

|

Types of Water-Activated Tape Available from Azapak

Azapak offers a focused range of water-activated paper tapes for different sized packages and levels of security. Every tape option is designed to provide consistent adhesion, durability, and sustainability, giving businesses confidence in every shipment.

|

|

|

How to Apply Water-Activated Tape

If you’re wondering how to use water activated packing tape, the process is simple once you’ve got the right tools.

Manual ApplicationFor small businesses or low-volume packing, a Manual Water-Activated Tape Dispenser is an easy and affordable option. The tape feeds across a wet roller that moistens and activates the starch adhesive as you pull and tear it to the desired length from the roll. If you’re old enough to remember going to the post office to send a letter before the advent of peel and stick stamps (or even remember what a letter is), it’s quite similar to pressing the back of the stamp to the moist sponge before affixing it to the envelope. Similarly, once wet, the tape is ready to stick directly onto your cardboard box.

|

|

|

Machine ApplicationFor warehouses, distribution centres or other operations of significant size, Azapak’s VANTO® VT-330 Water Activated Tape Machine streamlines the process, helping you save time and ensure employee health. This efficient packaging solution delivers pre-cut lengths at the press of a button – ranging from 15cm to 210cm – and can dispense at speeds up to 30cm per second. It supports both standard and reinforced water-activated paper tapes up to 80mm wide.

Learn More About the VANTO VT-330 Water Activated Tape Machine |

Water-Activated Tape FAQs

Choose Azapak for Sustainable Packaging Solutions

At Azapak, we’re proud to partner with businesses to make their packaging processes more environmentally friendly. We offer a wide selection of sustainable products including kraft paper tapes, paper-based protective packaging and honeycomb paper padded mailers.

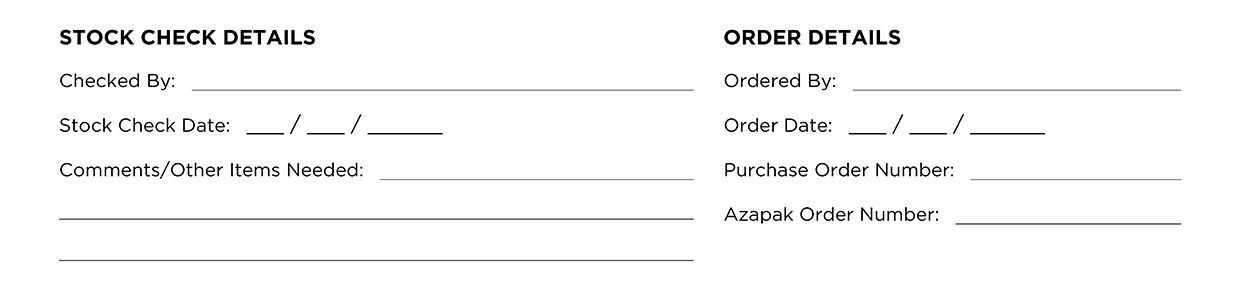

Need more details or want to arrange a sample? To learn more, call us on 1300 255 725 or email sales@azapak.com.au.