Glove ratings explained

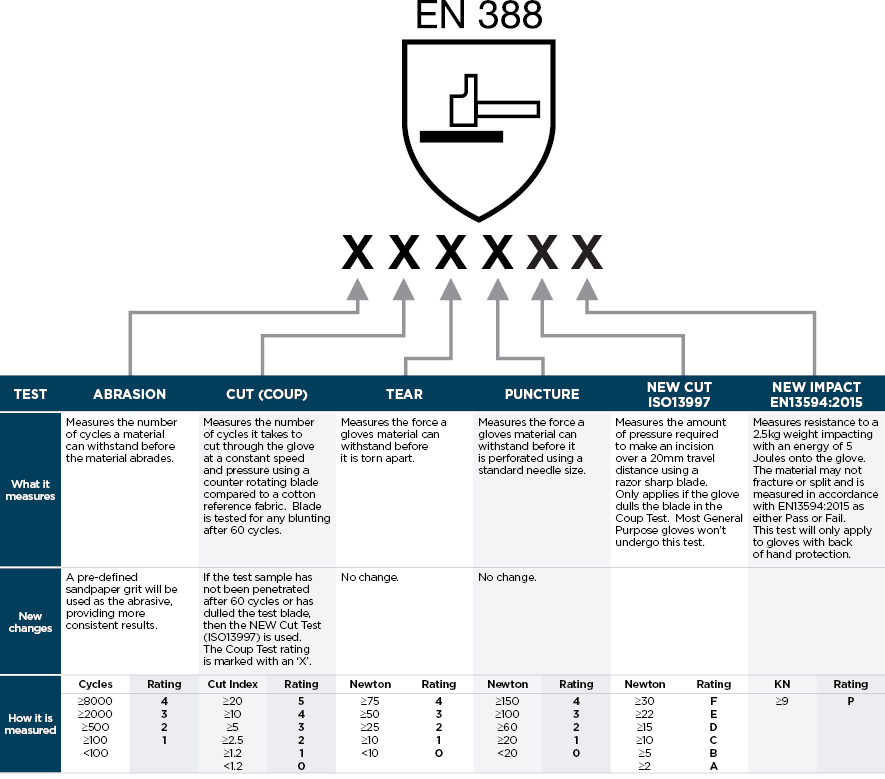

Glove ratings explainedIn 2016, the EN388 Mechanical Risks Standard was updated. This brought some important changes to the EN388 Glove Markings ratings. Azapak understands the importance of glove safety, so we’ve written this guide to help you understand the new glove ratings. What are glove ratings?To ensure operator safety, gloves are rated to the European EN388 Mechanical Risk Standard. This standard applies to protective gloves and refers to their resistance to abrasion, cut, tear, puncture and impact. It was updated in 2016 to make testing procedures and results more precise. Glove ratings are printed on each glove in the form of an icon (shown below). |

|

What are the new changes?

Each glove will now have 6 ratings instead of the usual 4. There are 2 new ratings, and 2 of the existing ratings have been modified. The 2 new ratings are a newer Cut Pressure Test and an Impact Resistance Test. Further details are as follows:

Change 1 - Cut Rating

Previously, level '5' was the highest cut rating available. However with the technology improvement of synthetic cut-resistant materials, it became clear that a higher standards test was needed to further seperate the field of Cut 5 rated gloves. Previous cut ratings were graded by measuring the amount of 'cuts' the glove would withstand before being cut through. The issue were that (1) Some new synthetic materials are so tough they were 'bluntening' the test blade which was skewing the results, and (2) there was obvious quality differences between those that passed the Cut 5 test (some only just passed, and some passed with flying colours and could obviously stand up to further testing).

The new standards bring in a new Cut Pressure Test, which is based on the amount of blade pressure (nM) the glove can withstand before being cut through. The rating is on an A-F scale with A being the lowest score and F being the highest score (See table below for more details).

Under the new standards, when doing the cut testing, the test blade is tested every 60 cycles for bluntening. If the blade is bluntened, they resort to the new Cut Pressure Test. Furthermore, if any glove passes with a Cut 5 Standards, they do a second test with a new Cut Pressure Test. The Cut Rating will be marked with an X, and the Cut Pressure Test rating delivered on the A-F scale. So essentially, there is now no longer any such things as Cut 5 Glove.

Change 2 - Impact Resistance

This new rating relates to gloves that have protective properties with additional protective properties on the palm, back of hand, or across the knuckles. The test simply delivers a Pass (P) or Fail (F) result. As this test is not applicable to each glove, not all gloves are rated with this standard. An X rating is marked on the glove if the glove has not been tested or if the test is not applicable to the glove.

How to interpret glove ratings

Further info

For further information on glove ratings, please contact our team.