STRAPPING MACHINES

Upgrade Operations with a Plastic Strapping Machine

Whether you're strapping up a few boxes, bundling items together or looking for high speed options to process a high volume of packages in an automated production line, Azapak’s automatic strapping machine range delivers reliable performance and serious efficiency gains to the Australian market.

From compact semi-auto units to high-output automatic strapper machines, our poly strapping machine range caters for light to heavy duty applications across a wide range of industries. All models are backed by local support and readily available spare parts.

Speak with a strapping machine specialist today. Call 1300 255 725 or email sales@azapak.com.au.

Plastic Strapping Machine Benefits

Every business handling cartons or boxed stock can benefit from a dedicated packing strap machine. Key advantages include:

- Increased speed – Enables faster packing and despatch by strapping cartons in seconds.

- Lower labour costs – Reduces the need for manual tensioning, sealing, or cutting.

- Consistent quality – Maintains uniform tension across all strapped boxes for better load security during transit and storage.

- Ergonomic operation – Designed to minimise repetitive strain and physical effort.

- Space-efficient design – Compact units integrate easily into existing warehouse or packing line setups.

From ecommerce warehouses to manufacturing despatch lines, automatic strapping tools deliver real efficiency gains.

Corner Protectors to Improve Pallet Stability and Appearance

Optional cardboard or plastic corner protectors slot over the edges of packed boxes and prevent the tensioned strap from cutting into cartons. This not only improves the stability and safety of the load, but also prevents ugly crushing, which can lead to stock damage and potential rejected deliveries.

Rent or Buy with Azapak

All models in our poly strapping machine range are premium quality, backed by full-service support and spare parts availability. We help you ensure you have the right tools for the job, your investment is protected, and our dedicated team is always ready to assist you. Whether you face a technical issue or require routine maintenance, our comprehensive support guarantees your strapping machines continue to operate efficiently, keeping your business running smoothly.

20+ Years of Strapping Experience

Azapak has been supplying quality strapping tools, machines and materials to Australian warehouses since 2004. Our long-standing expertise means we know what works — and what doesn’t — on the warehouse floor.

We support our strapper machines with:

- Local technical advice.

- Spare parts and servicing.

- Machine training for your operators.

- Fast, friendly support.

Choosing the Right Strap Machine

There’s no one-size-fits-all solution. We’ll help you choose based on:

- Box volume – Number of cartons you need to strap daily.

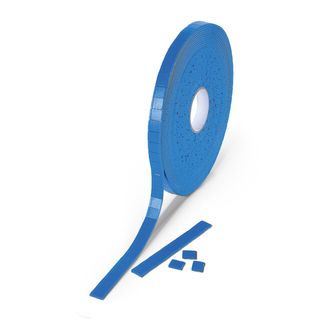

- Strap material – Polypropylene, PET or polyester options. Browse our range of strapping materials.

- Tension needs – From lightweight boxes to stronger tension requirements.

- Budget – Whether you're buying or renting.

Our recommendations are based on what’s proven to work in similar warehouse settings — not guesswork.

Chat with a plastic strapping machine expert today. Call 1300 255 725 or email sales@azapak.com.au.

Strapping Machine FAQs

Talk to the Strapping Experts Today!

Whether you're upgrading from hand tools or setting up a new packing area, Azapak can help you choose the right strapping machine for your operation — with the local support, accessories, and expertise to match.

Call 1300 255 725 or email sales@azapak.com.au to get started.