Your Guide To Packing Pallets

Pallets are a workhorse of modern industry, enabling suppliers to transport goods efficiently to their customers in a saleable condition. Poorly packed pallets can lead to lost revenue, reputational damage or even risk of injuries. So whether you're sending products across town or overseas, packing pallets properly is an essential part of the shipping process. This step-by-step guide covers everything from choosing a pallet to labelling and pallet shipping, ensuring your goods arrive at their destination safely.

Choosing the Right Pallet

Before you pack or ship pallets, selecting the correct base is essential. Different pallets offer distinct advantages depending on your shipping needs, warehouse setup and industry requirements.

Wooden Pallets

This timber variety is what most people imagine when you hear the word “pallet”. Thanks to their cost-effectiveness and wide availability, they’re a fixture of modern logistics. They are made of either softwood or hardwood, each suited to different load types, applications and budgets.

Softwood Pallets

The most common type of wooden pallet, typically made from treated pine. Softwood pallets are lightweight, affordable, and easy to handle, making them ideal for general shipping, retail, and agriculture. They’re also considered more sustainable, as softwood trees grow faster.

Hardwood Pallets

Made from dense timber like oak or gum, hardwood pallets are stronger and more durable, suited to heavy-duty loads and repeated use in warehouse and logistics operations. They have a higher upfront cost but offer greater longevity over time.

Plastic Pallets

Durable, weather-resistant, and reusable across many industries, these are ideal for operations prioritising hygiene or long-term use. Their uniformity makes them compatible with materials handling equipment, though upfront costs are higher.

Custom Pallets

For specialised loads or non-standard dimensions, bespoke pallets can deliver better weight distribution and proper support during transit. Customisation can also include branding or unique materials for added value.

Export Pallets

Compliant with ISPM-15 regulations, these are treated to prevent the spread of pests across borders – essential for international pallet shipping.

Retail Display Pallets

Typically smaller and lighter, these pallets move goods directly from the warehouse to the retail floor. Many large retailers, including fresh food giants Coles and Woolworths, may have specific palletising requirements – always check requirements to avoid additional costs from rejected deliveries.

Standard Sizes of Pallets – Domestic vs International

For most domestic freight, the Australian standard pallet is the go-to. But if you’re making shipments overseas, observe the relevant export-compliant sizes to avoid delays, repacking or added costs.

Here’s a breakdown of commonly used pallet dimensions in Australia and beyond:

Australian Standard Pallet

Size: 1165mm x 1165mm

Standard: AS:4068-1993

Use: Optimised for Australian warehouses and modes of transport, particularly on Australian racking systems and trucks. Best for domestic pallet shipping. Australia has a different class of pallet designed for global trade (see below).

Australian Export Pallet

Size: 1100mm x 1100mm

Use: Tailored for global shipping – pallet dimensions fit more efficiently in ISO-compliant shipping containers and are often treated to meet export regulations like ISPM-15.

Other Common Pallet Sizes

Euro Pallet: 1200mm x 800mm – widely used across Europe.

US Export Pallet: 1200mm x 1000mm – common shipping pallet for North American markets.

Custom Pallets: Built to meet specific size or load-bearing requirements for specialised freight.

Before you ship, always confirm which pallet format is preferred by your freight provider, customer, or destination country. Using the wrong size can lead to handling delays, rejection of goods, or unnecessary repacking costs.

What is a “Skid” in Shipping Terms?

A skid is similar to a pallet but lacks the bottom deck. It’s easier to drag and cheaper to make, but provides less stability for stacking or wrapping.

How to Pack a Pallet – Step by Step

Correct pallet packing isn't just about making everything fit – it’s about maintaining a steady and robust stack, protecting your stock from damage and ensuring cost-efficient shipping from the storeroom to the delivery bay.

-

Start with a stable base

Lay heavier cartons at the bottom, ensuring even weight distribution to maintain balance and stability. Use interlocking or brick-stacking patterns where you can, avoiding overhang. -

Stack items in layers

Build in uniform, flat layers. Gaps reduce stability and allow for shifting during transport. If you have mixed sizes, try to nest smaller boxes into spaces without creating unevenness on the top surface.

How High Can You Stack the Pallet?

When considering factors like total capacity (how many cartons on a pallet load), a general rule of thumb is not to build the stack higher than 2.5 metres. This safeguards both personnel and the cargo from injury or damage.

The total number of cartons you can safely fit depends on the size of your pallet and the individual items of freight.

A load composed of many small cartons might contain as many as 10 items per layer up to 8 layers high (80 cartons). If you have larger boxes the total might be less than half that number. -

Fill gaps where possible

Use dunnage, airbags or other void fillers to improve protection inside cartons and between layers. Avoid leaving empty spaces, which reduce pallet integrity and increase the chance of crushing. -

Keep everything flat on top

Your pallet wrap and strapping work best with a level top surface. Uneven tops can lead to poor wrap coverage and pallet shifting in transit.

Wrapping and Securing Pallet Loads

Wrapping the cargo properly strengthens the pallet’s structure, providing structural integrity to minimise damage during transportation or storage.

Stretch Wrap / Stretch FilmStretch wrapping the palletised load is the go-to for most warehouses. Stretch film conforms to irregular shapes and provides:

For heavier or irregular loads, pre-stretch machines like our Vanto range of pallet wrappers reduce film use and improve wrap tension. |

|

Pallet Strapping

Binding straps around the load adds vertical stability where stretch wrap alone isn’t enough. It helps prevent shifting, especially with tall, or irregular loads. Azapak provides a comprehensive range of strapping materials and additional protective items like pallet corner protectors to prevent straps from cutting into the cardboard.

Polypropylene Strap

An economical option good for bundling cartons and securing light pallets. Easy to apply by hand or with manual tools. Available in standard and heavy-duty variants with break strains up to 400kg.

Polyester (PET) Strapping

A plastic strap with added durability and tensile strength. A modern alternative to steel, it works with hand tools, battery units or machines. Recyclable and rust-free.

Composite Strapping

Made from reinforced polyester fibres, this type of strap is strong, flexible, and safer than steel. Great for outdoor use thanks to its UV-resistant coating.

Steel Strapping

Metal banding offers the highest strength for heavy-duty loads like machinery or building supplies. Best for demanding industrial or export use.

Woven Polyester Strap

This woven strap is tough but soft, making it perfect for transport restraints. Tensioned with hand tools and secured with buckles.

Pallet Strapping Tape

This high-tensile, stretchable adhesive tape can be applied in addition to or instead of other forms of strapping for an added stabilising layer.

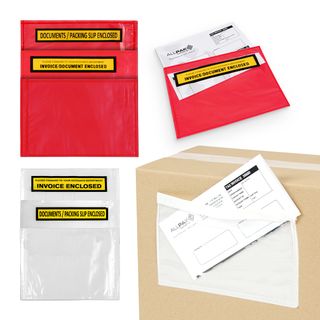

Labelling and Loading

Label ClearlyPlace waterproof labels on at least two sides. These should include:

Ensure forklifts can access all four sides, even after labelling. |

|

|

Move to Dispatch Point with Pallet JacksIf possible, you can load your pallet close to the dock or bay where the pallet will be loaded into a truck or other vehicle, cutting down on unnecessary handling. Always use mechanical aids like pallet jacks or forklifts – loaded pallets can easily exceed one tonne. We recommend:

|

Final Checks Before You Ship Pallets

Before you transport pallets off-site, run through a final checklist to avoid rejected pallets or shipping delays. Use these criteria based on best practice:

- Load is evenly stacked with no overhanging items.

- Boxes and crates are properly secured with wrap, strapping or tape.

- All correct labels are firmly applied and clearly visible.

- Any specific customer requirements (pallet type, size, labelling, etc.) have been followed.

- Weight and contents are documented for quality control and compliance.

Azapak – The Trusted Provider for all Packaging Needs

Whether you're managing internal transport, interstate shipping or export logistics, working with a reliable supplier gives you reliable solutions to support your supply chain. As a family-owned business with over 20 years’ experience, Azapak understands the needs of various industries. Our range of equipment and consumables are backed by expert advice plus local warranty and technical support.

Need assistance optimising your pallet packing and shipping process? Speak with an Azapak expert today. Call 1300 255 725 or email sales@azapak.com.au.